Hulls Design Improvements

Challenges and Reflections from RoboBoat 2025

At RoboBoat 2025, our team experienced a frustrating result: our ASV capsized during autonomous navigation, preventing us from completing the tasks. The structural causes were mainly due to the following two points:

- High Center of Gravity: The center of gravity of the entire vessel was too high.

- Instability of Hulls Shape: The “curved high-rocker (banana-shaped)” pontoons we previously used lacked stability on the water surface.

Drastic Structural Improvements for 2026

To prevent capsizing and ensure mission success, we have implemented the following structural changes for RoboBoat 2026:

- Hulls Shape Change (Flat Bottom)

We moved away from the unstable banana shape and newly designed and adopted “flat-bottom” pontoons. - Lower Center of Gravity

We physically lowered the mounting position of the enclosure (waterproof case) housing electronic equipment to reset the center of gravity lower. Additionally, we designed the hulls to house batteries and motor drivers internally, achieving an even lower center of gravity.

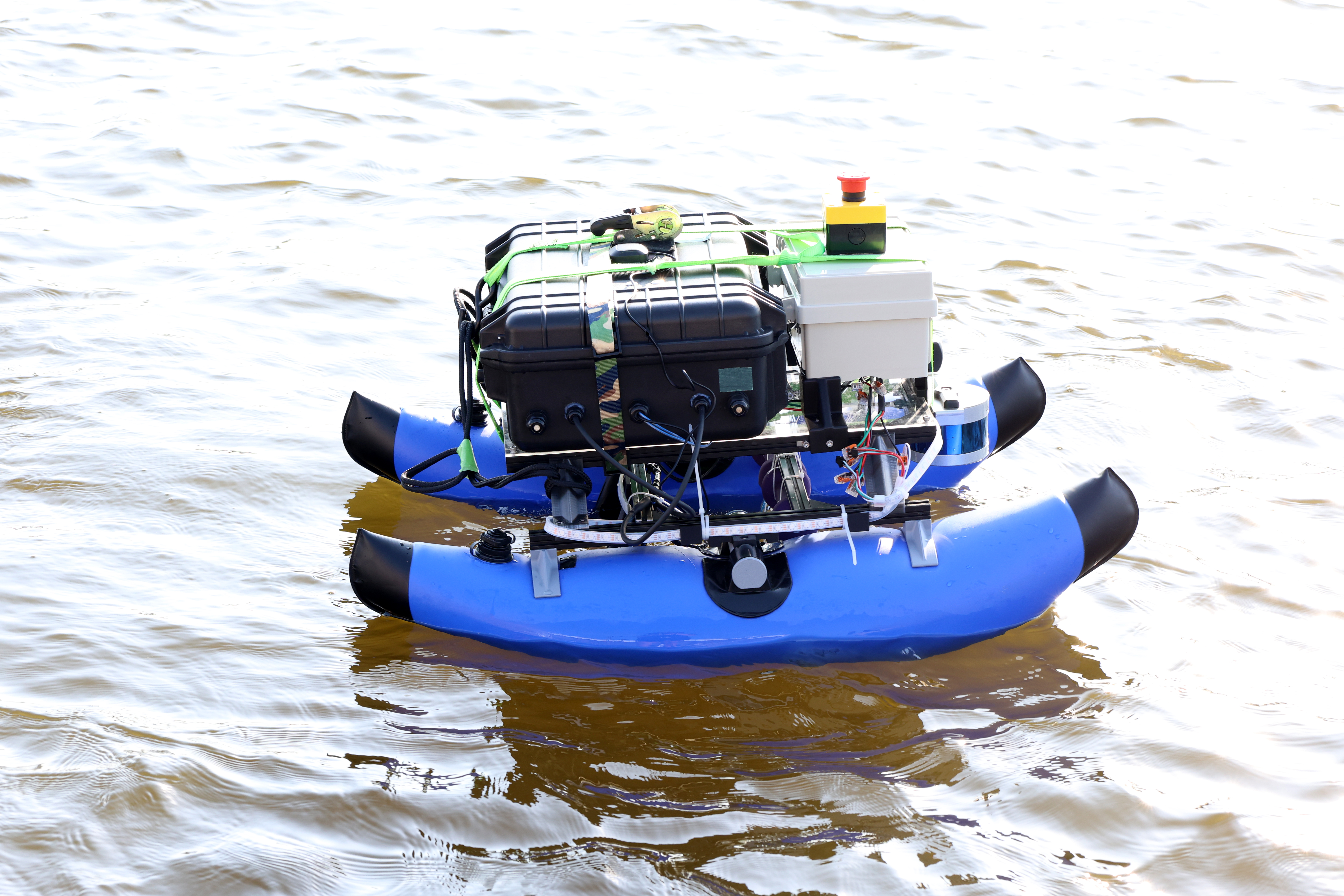

2025 Model

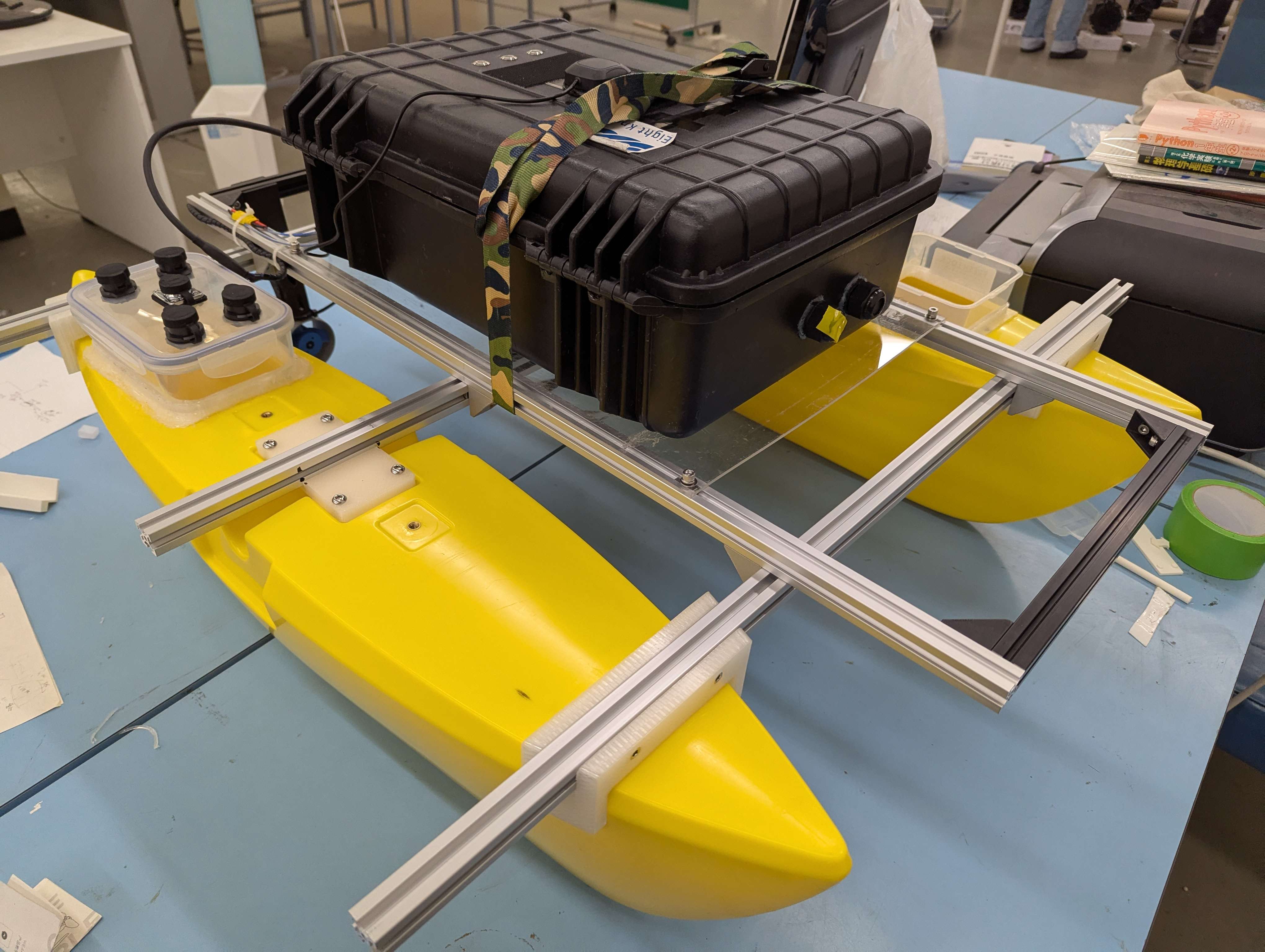

2026 Model

Fig 1. Hull comparison: 2025 (Left) vs 2026 (Right).

Other Detailed Design and Implementation

Ensuring Airtightness and Wiring

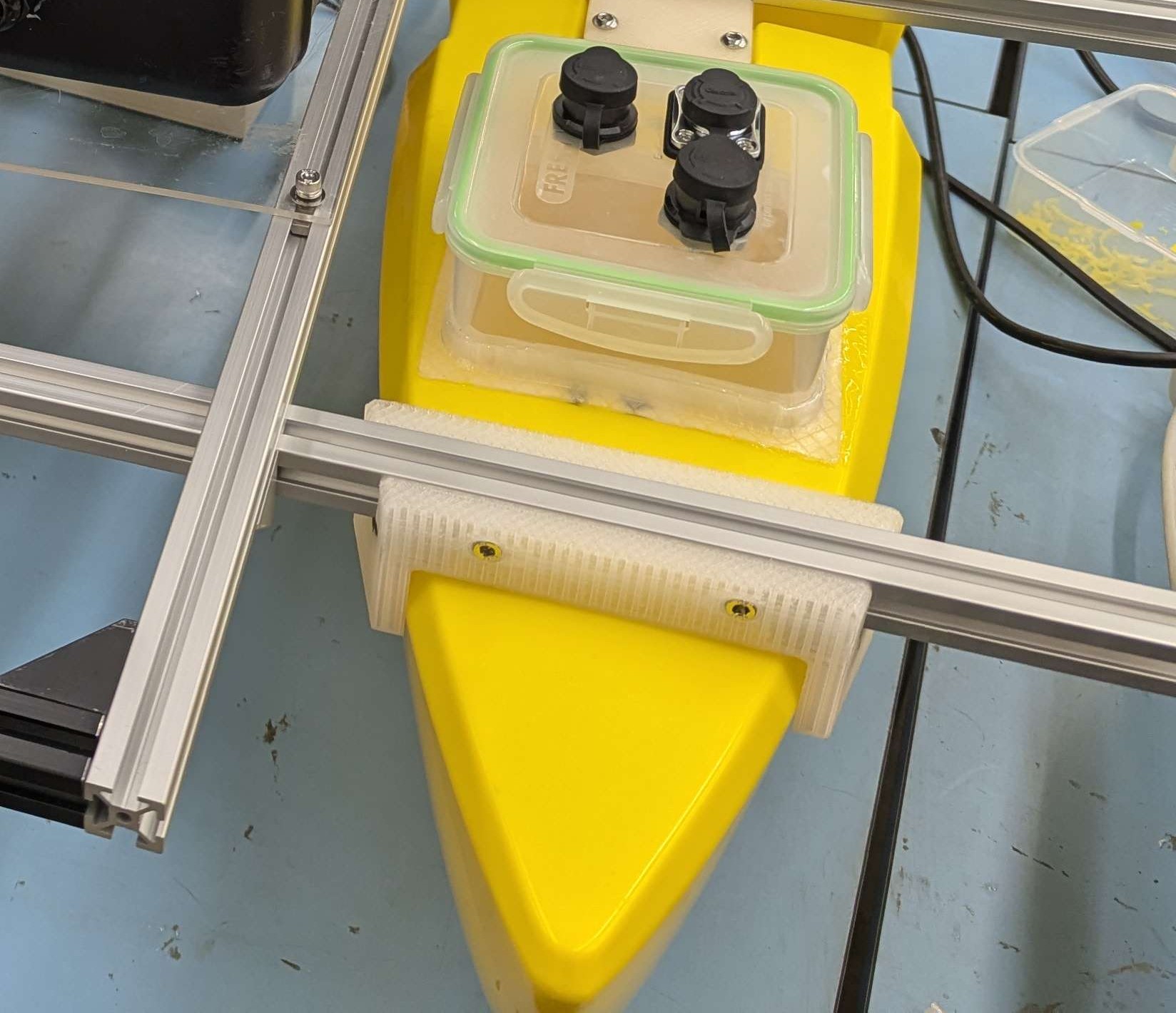

We redesigned the wiring path to connect the batteries and motor drivers inside the hull to the external electronics box. To pass the connectors through while maintaining airtightness, we adopted the following method:

- Drilled holes in the hull for wiring.

- Used Tupperware (sealed containers) to cover the holes and create an airtight compartment.

- Used epoxy resin for bonding to achieve complete waterproofing and airtightness (Fig 2).

Securing Connection Strength with the Frame

For connecting the hulls and the frame, we used a method of fixing them with a dedicated jig at one central point on each hull. However, with a single-point fixation, there was a risk of the jig breaking due to moment loads (twisting and bending forces). Therefore, we created additional support parts extending from the frame to support both ends of the hulls (Fig 2). This distributes the load and ensures a stable connection. The completed design fits within a compact size of less than 1 meter in both length and width. It can be easily carried by two people, significantly reducing the burden of transport and setup.

Fig 2. sealing using tupperware and support structure.